What is Stone Wool?

Stone Wool: Also known as mineral wool, rock wool, mineral cotton or mineral fiber. Stone wool is produced by spinning molten minerals or rocks into fiber strands. Learn More

Properties:

- Thermal Efficiency: High

- Fire Resistance: Excellent

- Acoustic Attenuation: Excellent

- Flexibility: Stone wool is inherently rigid due to the short length of the mineral fibers, making it non-bendable without the use of wired mats.

What sets Isover's ULTIMATE stone wool apart from traditional stone wool?

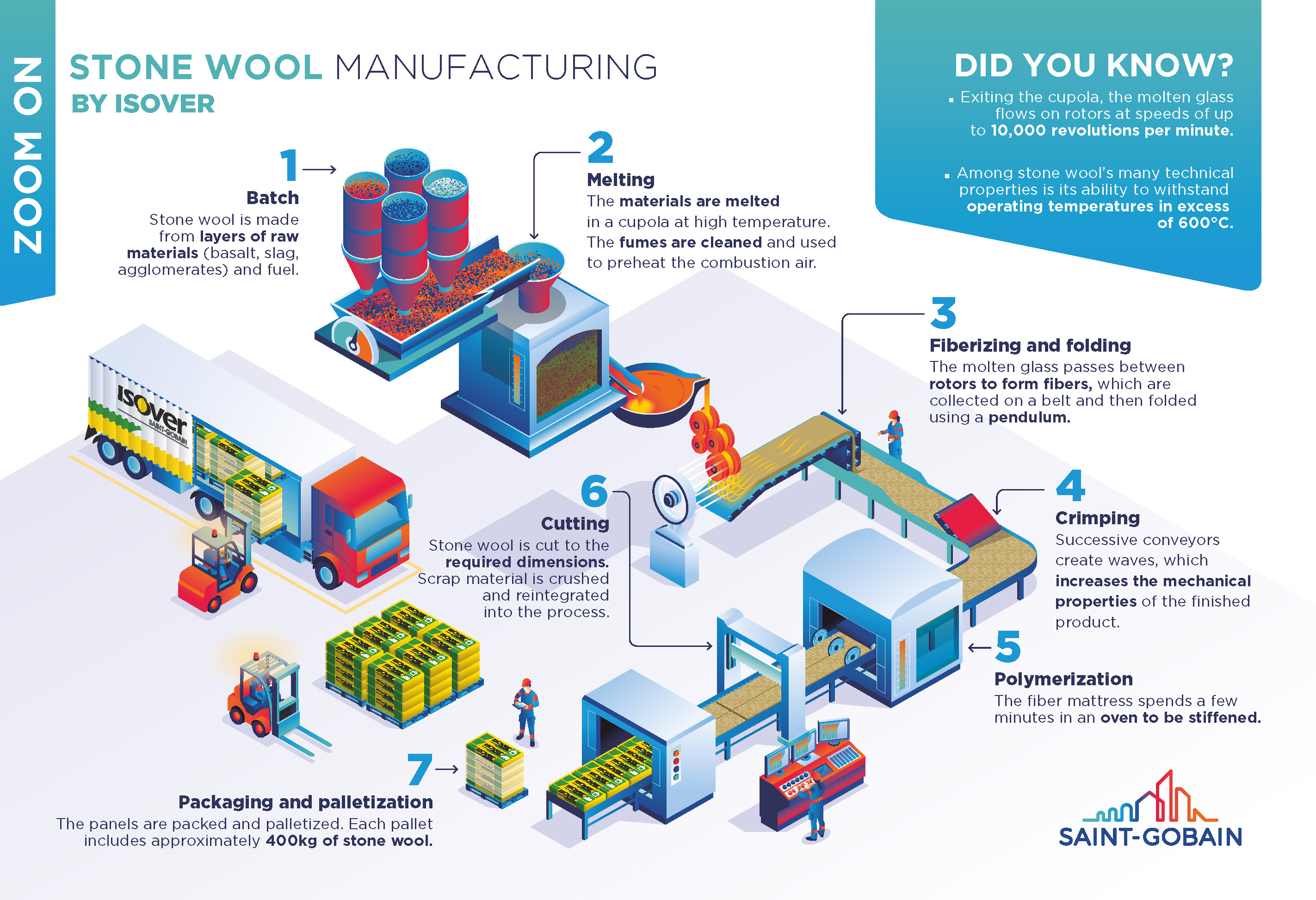

Innovative Production Process

Isover’s ULTIMATE product line, known as 'U Seaprotect' for marine applications, utilizes proprietary cutting-edge technology to significantly enhance the production process by eliminating 40% of shot and debris before heating. This refinement leads to several key improvements:

Long Fiber Strands: The technology employed spins the molten stone into long fiber strands, allowing Isover U Seaprotect to bend around stiffeners without breaking and without the need for wired mats.

Reduced Thickness and Weight: The removal of shot and debris means the insulation can be thinner yet provide the same fire, thermal, and acoustic properties of thicker traditional stone wool. This translates to lighter products, and lighter ships.

What are some of the cost-saving benefits of using Isover?

Reduced Resource Usage: The streamlined production process uses less material, which not only lowers procurement costs but also diminishes labor efforts in handling, thereby decreasing overall project costs.

Transport and Storage Savings: Fewer trucks are needed for transportation, which reduces freight costs and carbon emissions. Additionally, the product's compactness saves valuable storage space. Lighter insulation aids in reducing a vessel's overall weight, leading to further savings in fuel and CO2 emissions as corroborated by IMO standards.

Installation Simplifications: With the material's bendability, installations involve less cutting and trimming, drastically lowering waste generation from 15% to approximately 5%. Isover's stone wool is available in rolls which are easier to handle and apply compared to traditional slabs, and the use of self-adhesive seam tape eliminates the need for additional adhesives, further speeding up the installation process and reducing labor and material costs.

Isover's ULTIMATE stone wool is not just an insulation product but a comprehensive solution that enhances operational efficiencies, reduces environmental impact, and offers significant cost savings, setting a new standard in the marine insulation industry. This innovation exemplifies the future of sustainable and efficient shipbuilding.

How can I order Isover U Seaprotect Insulation?

Imtra is the exclusive supplier for the U Seaprotect Marine insulation by Isover in the United States. We understand that every project is unique, and our team is here to help you determine the best applications for you. Whether you are an Arctic rated patrol vessel or a GOM supply ship, we have the expertise to help you properly estimate a complete insulation package. Our process includes the logistical considerations for the materials, freight, storage and more. To get started contact us.

What are the different facings available?

Isover insulation comes with many options including thickness, roll or slab and facing type. The facing you need for your application depends on many factors. While G220 and ALU1 are the most popular there are many more options.

G220 (White Glass Cloth) Facing

The G220 facing is made from white glass cloth and is designed for use in marine insulation applications that require a high degree of fire resistance and durability.

Properties:

- Fire Resistance: The glass cloth material is inherently fire-resistant, which makes it an excellent choice for marine applications where fire safety is a critical concern.

- Thermal Stability: It can withstand high temperatures, making it suitable for areas exposed to significant heat.

- Mechanical Strength: Provides robust protection against mechanical damage, including punctures and tears, which is essential in harsh operational conditions.

- Aesthetics: The white color of the glass cloth offers a clean and professional look, which is often desired in visible areas aboard ships.

Applications:

- Engine Rooms: Due to its high thermal and fire resistance, G220 is ideal for insulation in engine rooms where temperatures are high, and fire risk is significant.

- Kitchens and Galley Areas: Places aboard ships where fire safety and cleanliness are paramount.

- High-Temperature Areas: Suitable for areas near boilers, furnaces, or any machinery that emits a lot of heat.

- Visible Sections: Its neat appearance makes it suitable for areas that are not typically covered up, like ceilings and partition walls within passenger ships.

ALU1 (Aluminum) Facing

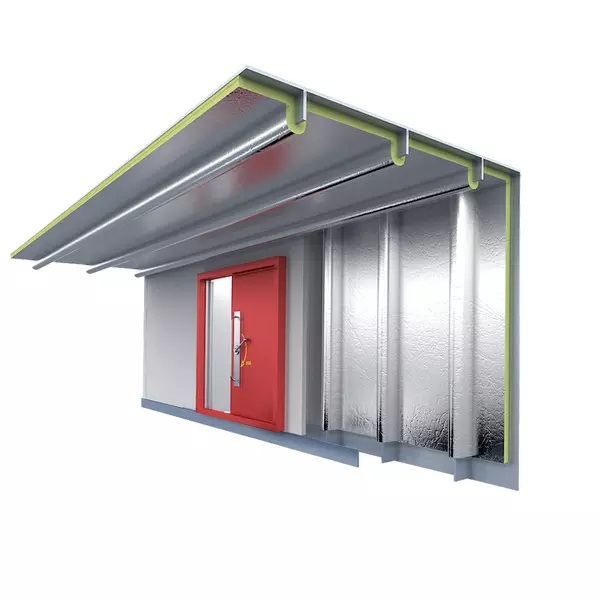

ALU1 facing consists of an aluminum foil layer and is used extensively in marine and offshore insulation solutions where excellent vapor barrier properties are required alongside reflective heat insulation.

Properties:

- Vapor Barrier: Aluminum is an excellent vapor barrier, effectively preventing moisture transmission that can degrade insulation and structural integrity.

- Reflective Insulation: Reflects thermal radiation, which helps in reducing heating and cooling demands, thereby enhancing energy efficiency aboard vessels.

- Corrosion Resistance: The material is resistant to corrosion caused by marine environments, which include high humidity and salt spray.

- Lightweight: Aluminum facings add minimal weight to insulation products, an important factor in marine applications where extra weight can affect fuel efficiency and stability.

Applications:

- HVAC Ducts: Protects insulation on HVAC ducts from moisture while improving energy efficiency by reflecting heat.

- Pipes: Used to insulate pipes, particularly those carrying hot or cold substances, to prevent condensation and maintain temperature levels.

- Exterior Walls: Applied on external walls where moisture barrier and thermal reflectivity are needed to improve comfort and reduce energy costs.

- Underdeck Areas: Helps in preventing moisture-related issues and enhancing thermal insulation in exposed underdeck areas.

G120 Glass Cloth Facing

G120 is a black glass cloth facing used in marine insulation products to enhance their mechanical protection and fire resistance while maintaining a clean and professional appearance.

Properties:

- Fire Resistance: High resistance to fire, does not promote flame spread, making it suitable for stringent fire safety requirements in marine environments.

- Durability: The glass cloth material provides excellent tensile strength, making it resistant to tears and mechanical wear.

- Thermal Stability: Maintains its integrity under high temperatures, suitable for high-heat areas around engines and machinery.

- Aesthetic Appeal: Offers a neat, black finish that does not easily soil or degrade, ideal for visible areas where appearance is important.

Applications:

- Engine Rooms: Protects insulation on pipes and equipment close to high temperatures, where the risk of fire and heat exposure is significant.

- Visible Areas: Used in passenger ships and visible sections of cargo ships where a clean appearance is desired.

- High-Temperature Areas: Ideal for applications involving high temperatures but where the insulation also needs to be visible and presentable.

G420 Glass Cloth Facing

G420 is another variant of white glass cloth facing, similar to G120 but typically designed for even higher specifications, particularly in thermal and acoustic insulation applications.

Properties:

- Enhanced Fire Resistance: Like G120, G420 provides excellent fire resistance but with improved performance characteristics suitable for more demanding applications.

- Superior Durability and Tensile Strength: Offers increased resistance to physical damages such as tears and punctures, which is crucial in high-traffic or mechanically exposed environments.

- High Thermal and Acoustic Performance: While maintaining the benefits of G120, G420 adds better acoustic dampening properties and thermal resistance, suitable for environments where noise reduction is also a priority.

- Visual Consistency: Provides a white, clean look that helps in maintaining an unobtrusive and professional appearance in visible insulation applications.

Applications:

- Acoustic Dampening: Ideal for use in areas where sound absorption is crucial, such as in HVAC systems and cabin walls aboard ships.

- Fire-prone Areas: Enhanced fire resistance makes it suitable for areas with higher fire risks, including kitchens and engine rooms.

- Thermal Insulation: Effective in high-temperature zones where maintaining a lower ambient temperature is essential for safety and comfort.

B-GL (Glass Cloth Outside) Facing

B-GL facing involves a glass cloth exterior which is primarily used for its high tensile strength and excellent fire resistance properties. This type of facing is beneficial in harsh environments where mechanical durability and resistance to high temperatures are required.

Properties:

- Fire Resistance: Provides excellent resistance to fire, helping to prevent flame spread in critical areas.

- Durability: The glass cloth material is robust, providing substantial protection against physical damage such as scratches, punctures, and tears.

- Thermal Stability: Effectively withstands high temperatures, making it suitable for areas near engines, boilers, and other heat-generating equipment.

- Aesthetic and Functional Flexibility: While it maintains a utilitarian design, it can be used in areas where both appearance and performance are important.

Applications:

- Engine and Machinery Rooms: Where high temperatures and potential mechanical impacts are common.

- Areas Requiring Frequent Maintenance: Provides ease of cleaning and durability in high-traffic areas.

- Fire Safety Critical Locations: Such as near fuel lines, generators, and other flammable material storage areas.

B-AL (Aluminum Outside) Facing

B-AL facing features an aluminum foil exterior which acts as an excellent vapor barrier and reflects thermal radiation, enhancing the insulation's effectiveness. It is typically used in environments where moisture resistance is crucial.

Properties:

- Moisture and Vapor Barrier: Excellent at preventing moisture ingress, which can degrade insulation materials and reduce thermal efficiency.

- Reflectivity: Reflects heat and prevents the transfer of radiant heat, contributing to better thermal control.

- Corrosion Resistance: Aluminum is naturally resistant to corrosion, particularly important in salty, marine environments.

- Lightweight: Despite its protective qualities, it remains light, which is advantageous in applications where additional weight could be detrimental.

Applications:

- HVAC Systems: Ideal for duct insulation where preventing condensation and controlling heat loss are critical.

- Exterior Walls and Ceilings: Used in areas that experience direct exposure to the external environment, providing a weather-resistant layer that also enhances thermal performance.

- Underdeck and Exposed Surfaces: Protects against the harsh marine environment, preventing moisture-related issues and enhancing energy efficiency.

Unfaced Insulation

Unfaced insulation is simply the insulation material without any protective or functional facing. This type of insulation is used in applications where the inherent properties of the insulation material itself are sufficient for the performance requirements of the installation area.

Properties:

- Thermal Insulation: Provides inherent thermal resistance that helps in reducing heat transfer and maintaining temperature control within the environment.

- Fire Resistance: Many insulation materials, like mineral wool or fiberglass used in U SeaProtect™ products, are naturally fire-resistant and do not necessarily require additional facings to meet certain fire safety standards.

- Acoustic Performance: Offers good sound absorption properties which help in reducing noise pollution and enhancing acoustic comfort in living and working areas on marine vessels.

- Environmental Resistance: Depending on the material, some unfaced insulations can resist moisture and prevent the growth of mold and mildew, although they are generally less protected compared to faced options.

Applications:

- Interior Walls and Ceilings: Used within interior walls and ceilings where the primary requirement is thermal and acoustic insulation without the need for a vapor barrier.

- Dry Environments: Ideal for areas that are not exposed to high humidity or direct contact with water.

- Between Other Materials: Often installed between other building materials that may provide the necessary environmental protection (e.g., inside wall panels, above suspended ceilings, in floating floors).

- Retrofit Applications: Suitable for adding extra insulation to existing structures where external facings might not be feasible or necessary.

Advantages of Unfaced Insulation:

- Versatility: Can be used in a variety of applications where facings are not required, offering flexibility in use.

- Cost-Effectiveness: Generally less expensive than faced insulation because there is no additional cost for the facing materials and the manufacturing process is simpler.

- Ease of Installation: Without the bulk and rigidity of facings, unfaced insulation is often easier and quicker to install. It can be cut to fit irregular shapes and sizes easily, making it ideal for custom applications.

- Breathability: Allows for better moisture control within walls as it lets the assembly breathe, reducing the risk of mold and moisture damage in certain applications.

Considerations:

While unfaced insulation is beneficial in many scenarios, it is crucial to assess the environmental conditions and specific requirements of each application to determine if a facing might be necessary for additional protection. In environments with high humidity, varying temperatures, or exposure to elements, faced insulation might offer better longevity and effectiveness.

V1 Facing

V1 is a vapor barrier facing commonly used by OEMs in marine and offshore insulation applications. It is designed to provide excellent moisture resistance and mechanical protection.

Properties:

- Moisture Resistance: High resistance to water vapor transmission, effectively preventing moisture ingress which can degrade the insulation material and reduce its thermal performance.

- Mechanical Protection: Offers a robust cover to the insulation, protecting it from physical damages during installation and operation.

- Fire Resistance: Complies with fire safety standards required in marine applications, contributing to the overall safety of the insulation system.

Applications:

- HVAC Systems: Ideal for use in heating, ventilation, and air conditioning systems where controlling moisture is critical to maintaining system efficiency and preventing mold growth.

- Pipes and Ducts: Provides a protective and insulative layer around pipes and ducts, helping to maintain temperature and prevent condensation.

V2 Facing

V2 facing is similar to V1 in terms of its use as a vapor barrier but includes additional properties suitable for more demanding environments.

Properties:

- Enhanced Moisture Resistance: Like V1, V2 provides excellent resistance to water vapor but with enhanced performance that makes it suitable for extremely humid or wet conditions.

- Increased Durability: The material used for V2 facing is typically tougher than V1, providing better resistance to punctures and tears.

- Fire and Thermal Resistance: Offers significant resistance to fire and heat, maintaining its integrity in fire-prone areas and under high temperatures.

Applications:

- Below Deck: Perfect for areas below the water line where high humidity levels are common and moisture control is crucial.

- Exposed Areas: Can be used in parts of the ship that are exposed to harsh environmental conditions, providing reliable insulation protection.

What are the differences between “Easy Handling,” “Full Comfort,” and “Even Lighter” designations?

The terms "Easy Handling," "Full Comfort," and "Even Lighter" denote specific features designed to meet varied operational and installation needs.

Easy Handling

Easy Handling insulation products are designed to facilitate easier installation, which can significantly reduce labor time and costs. These products are engineered for convenience, from transportation through to installation.

Features:

- Lightweight: Less dense materials are used to reduce the weight of the insulation, making it easier to carry and maneuver during installation.

- Flexible Dimensions: Available in various sizes and forms (e.g., rolls, slabs, pre-cut shapes) to suit different spaces and shapes aboard vessels, minimizing the need for onsite adjustments.

- Tool Optimization: Manufactured to be compatible with standard installation tools and techniques, which simplifies the installation process.

Applications:

- Confined Spaces: Ideal for tight and hard-to-reach areas where maneuverability is limited.

- Quick Retrofitting: Used in projects requiring quick upgrades or replacements, where minimal disruption is desired.

- High Labor Cost Areas: Optimal for regions where labor costs are high, as the easy-to-handle nature of the insulation reduces installation time and effort.

Full Comfort

Full Comfort products emphasize enhancing the comfort aboard ships through superior acoustic and thermal insulation performance, aiming to create a more pleasant and livable environment.

Features:

- Superior Acoustic Insulation: Reduces noise pollution significantly, which is crucial in passenger and crew areas to ensure comfort and reduce stress.

- Enhanced Thermal Properties: Offers improved thermal resistance which helps in maintaining stable interior temperatures and reducing energy consumption related to heating and cooling.

- Health and Safety Compliance: Often includes materials that are non-irritant and do not emit harmful substances, ensuring safety and comfort for passengers and crew.

Applications:

- Passenger Cabins and Crew Areas: Ensures a quiet and thermally comfortable environment conducive to relaxation and operation.

- Recreational Areas: Ideal for places where noise reduction can enhance the usability and enjoyment of onboard facilities.

- Living Quarters: Applied in sleeping quarters to improve sleep quality and overall comfort.

Even Lighter

Even Lighter insulation products are developed to minimize the weight of the insulation solutions without compromising on performance. This feature is particularly valuable in the marine industry where weight impacts fuel efficiency and stability.

Features:

- Reduced Material Density: Utilizes advanced materials that provide the necessary insulation properties but at a lower weight.

- Innovative Manufacturing Processes: Incorporates technologies that reduce the overall weight of the insulation materials, such as using aerogels or hollow fiber structures.

- Optimized for Fuel Efficiency: Lighter weight contributes directly to lower fuel consumption, making it an eco-friendly option.

Applications:

- High-Performance Vessels: Suitable for ships where performance and speed are prioritized, and extra weight can adversely affect these parameters.

- Fuel-Sensitive Operations: Ideal for operations where fuel efficiency is critical, such as long-range shipping and operations in remote areas.

- Structural Integrity Concerns: Used in areas of the ship where reducing load is important to maintain structural integrity.

What standards and compliance apply to marine insulation?

Isover insulation products meet or exceed the following Certifications and Standards

IMO (International Maritime Organization) Standards

- IMO 2010 FTP Code:

- Part 1: Non-combustibility test (ISO 1182)

- Part 2: Smoke and toxicity test (ISO 5659-2)

- Part 5: Surface flammability test (ISO 5658-2)

- Part 6: Fire propagation test (ISO 5660-1)

These standards ensure that the materials are capable of limiting the spread of fire, producing minimal smoke and toxins, and resisting ignition.

MED (Marine Equipment Directive) Certification

- Indicates that the product complies with the EU's standards for marine equipment, permitting its use across European waters and on ships registered in EU countries.

- MED certification involves assessment by a notified body, which verifies compliance with the applicable IMO FTP Codes.

EUCEB (European Certification Board)

- Confirms that mineral wool fibers used in the products are bio-soluble and safe for use, meeting health standards that prevent risks related to inhalation.

ISO (International Organization for Standardization) Certifications

- ISO 9001: Quality management systems — Ensures that the products are consistently produced and controlled according to quality standards.

- ISO 14001: Environmental management systems — Demonstrates compliance with environmental management requirements, ensuring the products are manufactured in an eco-friendly manner.

CE Marking

- Proves that the insulation product meets EU safety, health, and environmental protection requirements, which is mandatory for products used within the European Economic Area (EEA).

Lloyd’s Register Approval

- Indicates that the products have been independently tested and meet the specific safety standards required in marine and offshore industries.

DNV GL Certification

- Products certified by DNV GL comply with rigorous quality and safety standards required for use in the maritime industry.

Bureau Veritas

- Certification from Bureau Veritas assures compliance with marine standards regarding safety, risk prevention, and quality.

ASTM Standards

- ASTM C612: Specification for mineral fiber block and board thermal insulation.

- ASTM E84: Test method for surface burning characteristics of building materials.

EN Standards

- EN 13501-1: Classification of materials for fire behavior.

- EN 13162: Specifications for mineral wool products.

Final Thoughts

With so many different options to choose from and dozens of different potential applications within any given ship, picking the right insulation for every area of the vessel can be a challenge. But it doesn't have to be, as the experts at Imtra are available and eager to find the right solution to fit your specific needs, so give us a call today to get started.